Catapult

For carrying out vehicle and organic/sub-system tests using standardized or internal methods

Maximum kinetic energy: 278 kJ

250 kW electric engine (traction force of 8T at 20 km/h and 2T at 60 km/h)

55 m test track fitted with rails for guiding sleds and a second test track for vehicles/sleds running on tires

A 420 T crash wall sized for withstanding impact loads, stabilized at 1600 kN

Seven sleds with different geometries/ weights for carrying out organic/sub-system tests

Instrumentation: Accelerometers, load cells (single or multi-axis – 3 or 6 components), strain gauges, displacement sensor, speed barrier, etc.

Two HYBRID III 50th percentile test dummies including 1 RS compliant to GMRT 2100 standards

128 measurement channels up to 100kHz per channel

Airbag firing timer

Fast motion cinematography: Seven digital video color cameras – resolution 1,024 by 1,024 pixels at 2,000 images per second (full size)

centre d’innovation

et d’essais technologiques

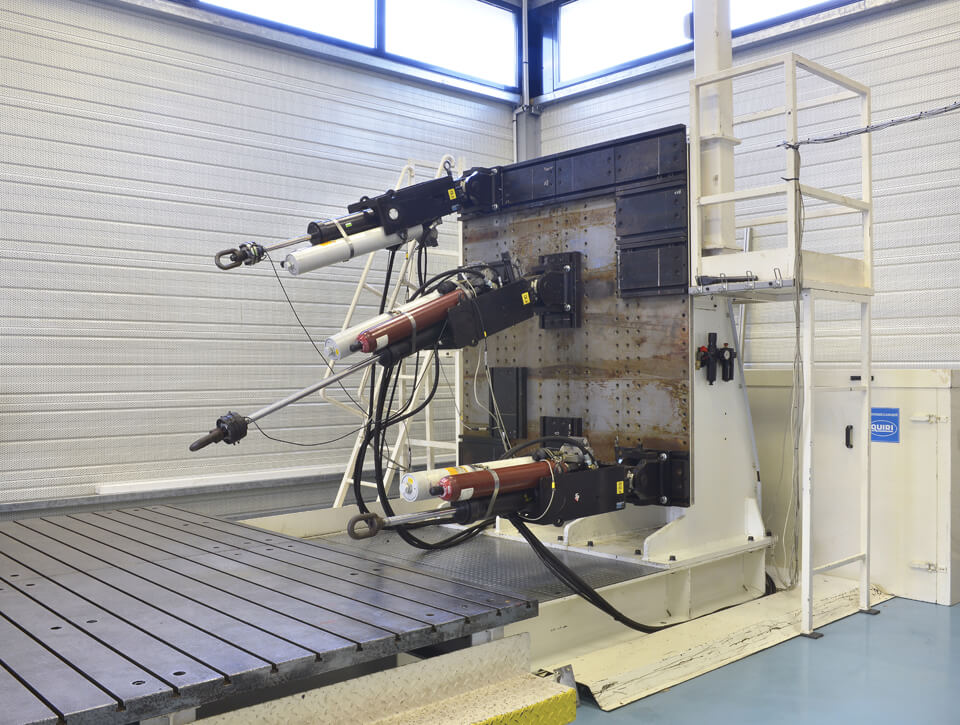

Pedestrian impact bench

For carrying out pedestrian protection tests and dynamic tests using

standardized or internal methods

Closed loop regulated hydraulic launchers:

Pedestrian launcher: 1500 J, 45 km/h max.

FMVSS201 launcher: 400 J, 24 km/h max.

Free-flight impactor: Head, legs

Guided flight impactor: Pelvis, customized impactor

Data acquisition systems and fast motion cinematography used in conjunction with those described for the catapult test bench

centre d’innovation

et d’essais technologiques

ECE R14 dynamic test bench

For carrying out ECE R14 tests and quasi-static and/or dynamic tests using standardized or internal methods

MOOG control electronics, MITS software, up to 2.5kHz per channel, 9 hydraulic cylinders with identical characteristics: stroke 600mm, force up to 50kN (load step-up time from 0.2s to 60s), maximum speed on full stroke up to 2.5m per second, test bench 3m x 5m

centre d’innovation

et d’essais technologiques

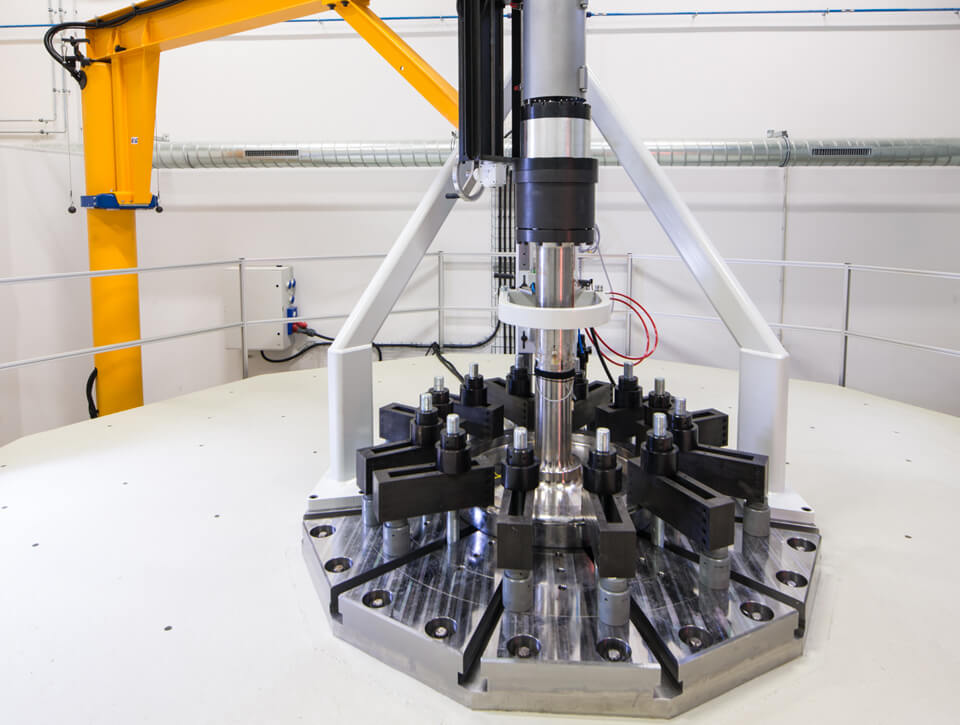

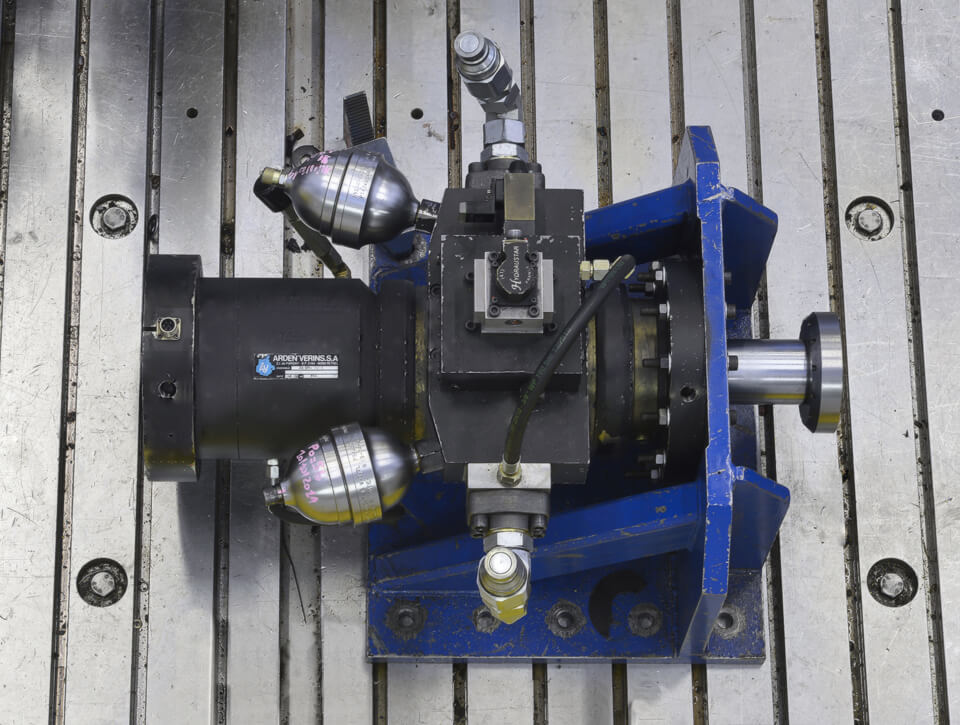

Hydraulic cylinder-mounted platform

For carrying out thermomechanical, dynamic and endurance tests and tests under quasi-static load (single or multi-axial) using standardized or internal methods

220 metric ton decoupling block

Floor surface 5m x 7m

5 hydraulic cylinders with the following characteristics:

| Stroke | 700 mm | 600 mm | 250 mm | 75 mm | 40 mm |

|---|---|---|---|---|---|

| Dynamic load | 14 kN | 165 kN | 66 kN | 11 kN | |

| Static load | 300 kN | 19 kN | 200 kN | 88 kN | 15 kN |

| Speed | 0.25 m/s | 2 m/s | 2.8 m/s | 1.5 m/s | 0.25 m/s |

INSTRON CONTROL ELECTRONICS, Labtronic 8800, 5kHz per channel

Instrumentation: Accelerometers, load cells (single or multi-axis – 3 or 6 components), strain

gauges, displacement sensor, etc.

Torque wrenches with temporal acquisition (2-25 & 10-100 Nm)

Ultrasonic thickness measurements with temporal acquisition (Sofranel)

Data acquisition systems and cinematography tools described for use with the catapult test bench can also be deployed

centre d’innovation

et d’essais technologiques

A drive and control unit for carrying out endurance tests in a climatic operating environment

For carrying out quasi-static and/or endurance tests at ambient temperature or during climatic cycles using standardized or internal methods

3 control unit with 4 to 11 channels (SDI, MOOG brand)

Electric and pneumatic actuators

Endurance tests in a climatic environment can be carried out using chambers with volumes from 430 liters to 10 m3

Temperature range: from -70°C to 180°C

Temperature variation at an average speed of 2°C per min.

Humidity range: 10%RH to 95%RH over a temperature range from +20°C to +90°C

Related resources:

Schneider M328 PLC with 10 input/output channels

GRAPHTEC GL7000 data acquisition units, 10 channels, voltages from 100mV to 100V, up to 1kHz TDK Lambda 80V, 42A, 3360W regulated power supply

centre d’innovation

et d’essais technologiques

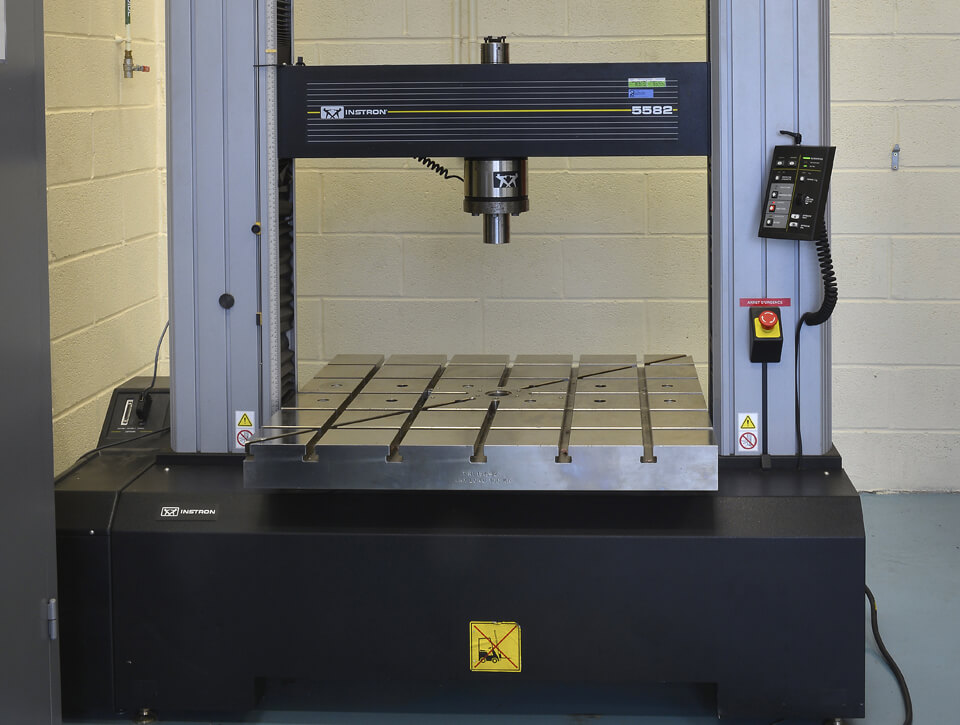

INSTRON 5582 tension-compression testing machine

For carrying out quasi-static tests using standardized or internal methods

Control software: Bluehill 3

Capacity 100 kN, speed adjustable from 0.001 to 500 mm/min

Acquisition speed for all channels: 500 Hz

Maximum displacement: 1735 mm, distance between columns: 934 mm

100 kN and 1 kN force transducers

Self-holding tension jaws with wedges. Capacity 5 kN

Strain gauges (Range Measurement. : 50 mm, maximum deformation: +50% -5%)

90° constant angle peeling device, 3-points bending

Means of acquisition described for the hydraulic cylinder platform can also be deployed

centre d’innovation

et d’essais technologiques

Shaker

coupled with

a climate chamber

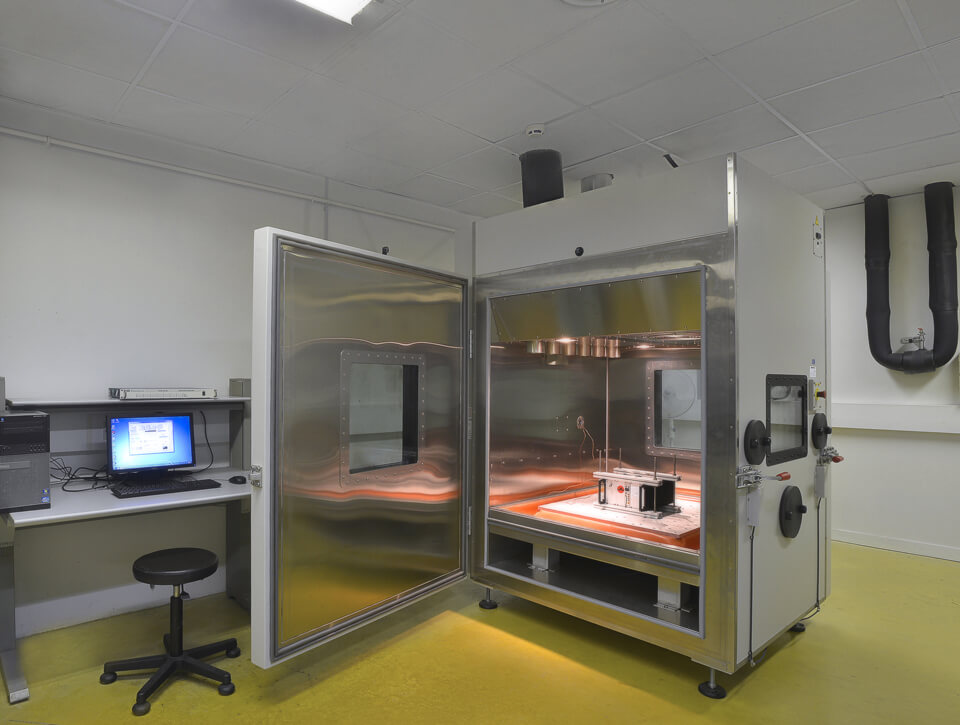

Vibration generator coupled with a climate chamber for carrying out combined vibration/climate tests using standardized or internal methods

Shaker: Electrodynamic shaker 30 kN, 5-3000 Hz

Vibration table 750 mm x 750 mm

Siemens control system, up to 40 channels

Control strategy: sinus, random (PSD), impacts, resonance or fixed frequency tracking, replication of road signs

A battery of accelerometers, composed of 100 channels (single and 3-axis, up to 500g, [-55°C, +288°C])

Climate chambers of 5.6m3 (2.5m x 1.5m x 1.5m)

Temperature range: from -60°C to 180°C

Temperature variation at an average speed of 2°C/min

Humidity range: 10%RH to 97%RH over a temperature range from +20°C to +90°C

IEC 61373 and DO 160 Section 7 and 8 Tests

centre d’innovation

et d’essais technologiques

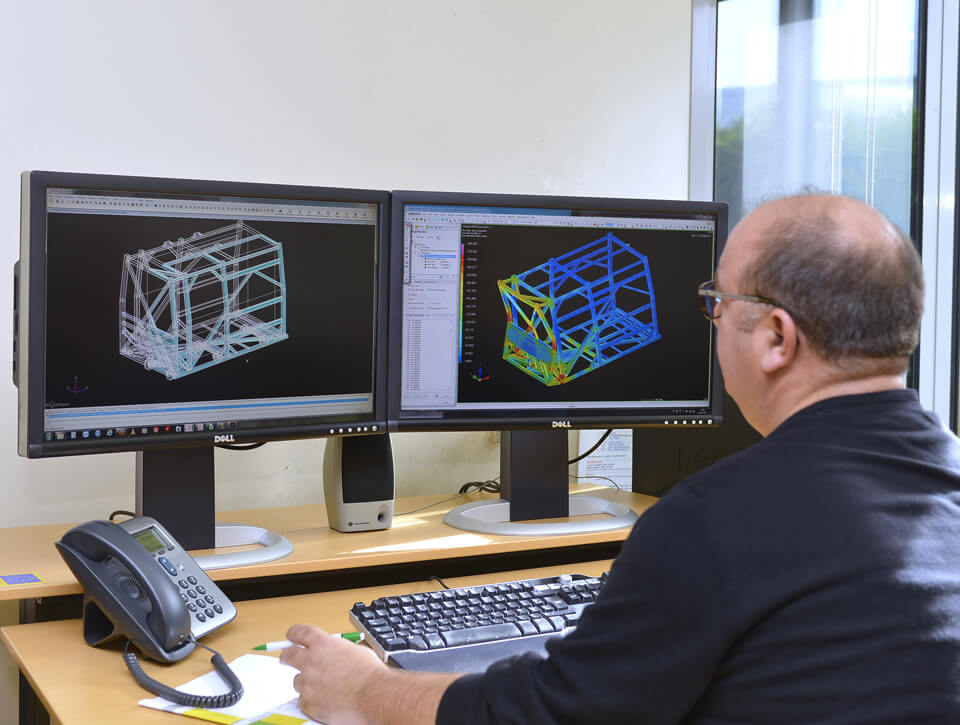

Means of vibratory characterization for structures

Experimental modal analysis and mode shape

Shock hammers 2.2 kN and 22 kN

Electrodynamic shaker 100 N, 300 N and 1000 N

A battery of accelerometers, composed of 100 channels (single and 3-axis)

Dynamic force cells up to 2000 N

Siemens acquisition system, 40 channels simultaneously at 20 kHz

120T decoupling block with a floor surface of 3.5m x 5.5m

centre d’innovation

et d’essais technologiques

Climate chamber with 6 DOF table for accelerated tests

Tests using the Halt & Hass method or similar

Qualmark chamber, Typhoon 2.5 model

Volume: 1.1m3 (1118mm x 1143mm x 889mm)

Temperature: [-100°C ; +200°C]

Temperature ramp of +/-60°C per min. with the equivalent of 30kg of steel

Table dimensions: 762 x 762 mm

Six degrees of freedom

Random signal on the frequency band ]0; 10kHz]

Acceleration up to 50gRMS

Physical limit of the table (in static): 145kg

Instrumentation: 1 thermocouple (on the part and/or in the gas volume) and 2 accelerometers for control, up to 6 complementary accelerometers and 10 complementary thermocouples

Spectrum and time signal analyzer:

centre d’innovation

et d’essais technologiques

Climatic chambers

Air-conditioning and aging tests

Volume 10m3: Inside dimensions L x W x H: 2m*2.5m*2m

Temperature range: -40°C to +120°C

When heated: Temperature variation at an average speed of 2°C per min.

When cold: Temperature variation at an average speed of 1°C per min.

Humidity: 25 at 97% RH over a temperature range of +20°C to +90°C

Volume 6m3: Inside dimensions L x W x H: 1.5m x 2m x 2m

Temperature range: -70°C to +180°C

Temperature variation at an average speed of 2°C per min.

Humidity: 10 at 98% RH over a temperature range of +10°C to +95°C

Volume 5.6m3: Inside dimensions L x W x H: 2.5m x 1.5m x 1.5m

Temperature range: from -60°C to 180°C

Temperature variation at an average speed of 2°C per min

Humidity range: 10%RH to 97%RH over a temperature range from +20°C to +90°C

Volume 3m3: Inside dimensions L x W x H: 1m x 2m x 1.5m

Temperature range: -60°C to +180°C

Temperature variation at an average speed of 2°C per min.

Humidity: 10 at 95% RH over a temperature range of +20°C to +90°C

Volume 2m3: Inside dimensions L x W x H: 1m x 2m x 1m

Temperature range: -40°C to +125°C

Temperature variation at an average speed of 2°C per min.

Humidity: 25 at 95% RH over a temperature range of +20°C to +90°C

Laboratory freezer with a useable volume of 430 liters

Inside dimensions L x W x H: 1430mm*490mm*650mm

Temperature range: From -10°C to -45°C

Heat chamber with a useable volume of 90 liters.

Inside dimensions L x W x H: 550mm*365mm*485mm

Temperature range: From +20°C to +220°C

centre d’innovation

et d’essais technologiques

Sun simulation test chamber

Insolation tests

Inside dimensions L x W x H: 6.2m x 6.6m x 3.5m

8 sunlight panels

15 IR lamps per panel

Power: 375W per IR lamp

Total sunlight power: 45kW

Ambient temperature range: +25°C to +40°C

Variation from +25°C to +40°C in about 30 min

Variation from +40°C to +25°C in about 1h

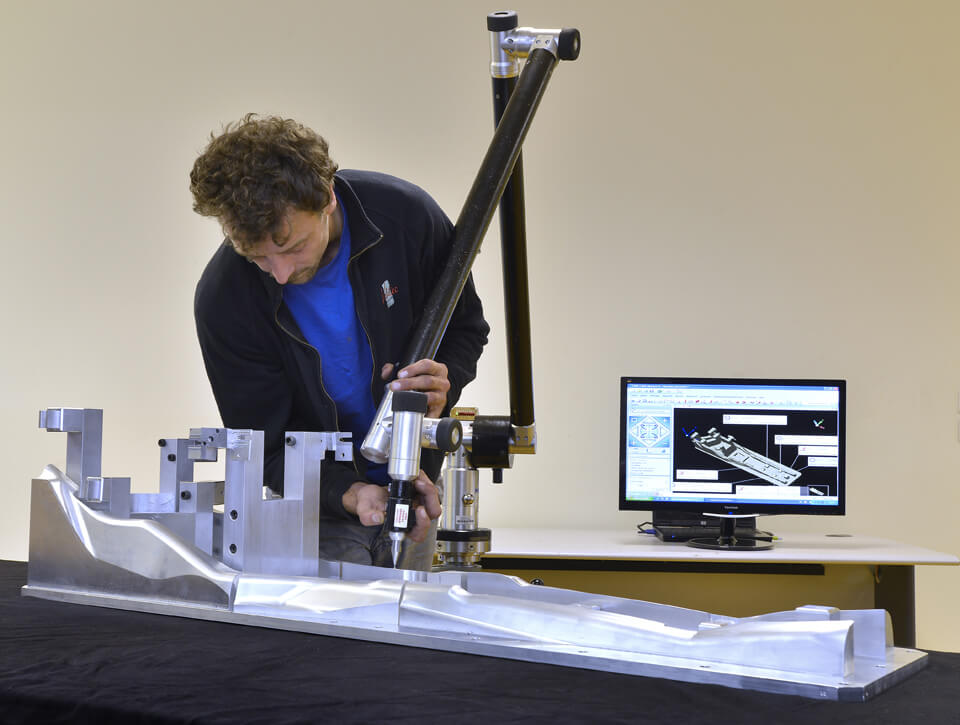

Metrological controls can be carried out before, during and after tests with the three-dimensional measuring arm or by contactless methods (photogrammetry, 3D digitization). gaps and flush, functional tests.

centre d’innovation

et d’essais technologiques

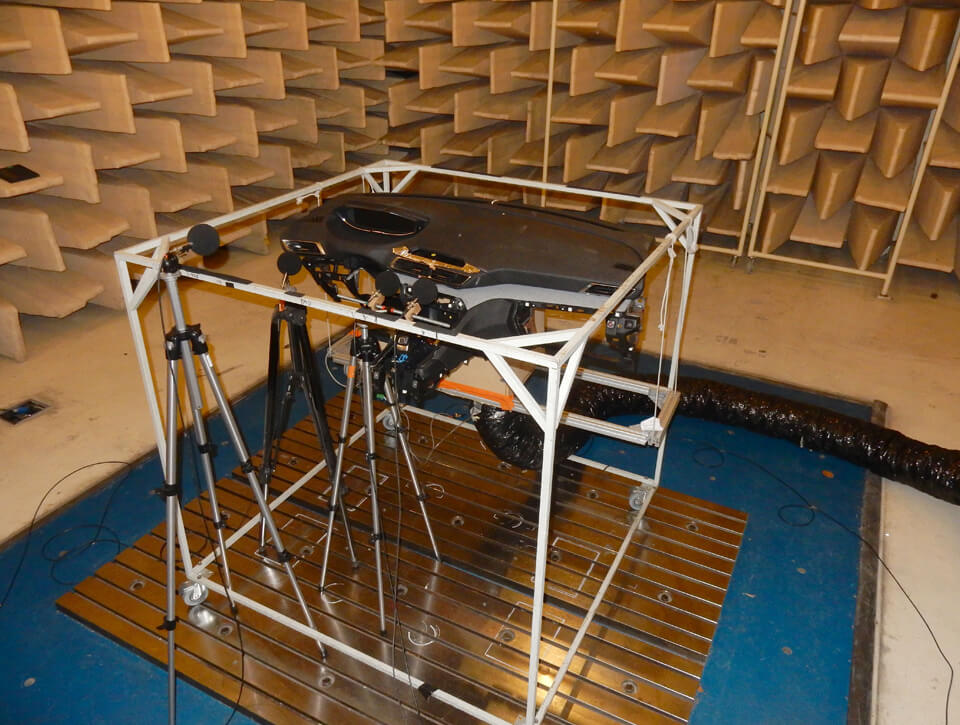

Semi-anechoic chamber with decoupling block

For carrying out acoustic, vibro-acoustic and aero-acoustic tests and identifying squeaks and rattles noise using standardized or internal methods

Volume: 200 m3

Decoupling block of 120T with a floor surface of 3.5m x 5.5m

Residual sound level: 20 dBA

Low decoupling frequency: 70 Hz

Shackers of 1,000N and 2,000N

Microphones, intensity probe and class 1 sound level meter

Apollo acquisition system with Samurai software

centre d’innovation

et d’essais technologiques

Aeraulic test bench

Aeraulic tests (overall or partial tightness, pressure loss, airflow distribution, direction capacity and homogeneity).

Aero-acoustic tests (tightness, subjective listening and/or noise level measurement, Leak detection)

Ventilator of 0.45 kW, 78 dBA,

Airflow: 0 to 700 kg per hour,

Plenum of 1m3,

Static pressure measurement : 0 to 1000 Pa,

Pressure loss measurement : 0 à 1000 Pa,

Dynamic pressure measurement (Debimo wings, Pitot tube): 0 to 1000 Pa,

Pressure loss of the bench at maximum flow rate: 23 Pa.

Instrumentation: mass flow meter from 10 to 1000m3 per hour, differential pressure transmitter 0-1000Pa, meteorological station, microphones, etc.

Aero-acoustic tests carried out in a hemi-anechoic chamber (see the description of the chamber)

centre d’innovation

et d’essais technologiques

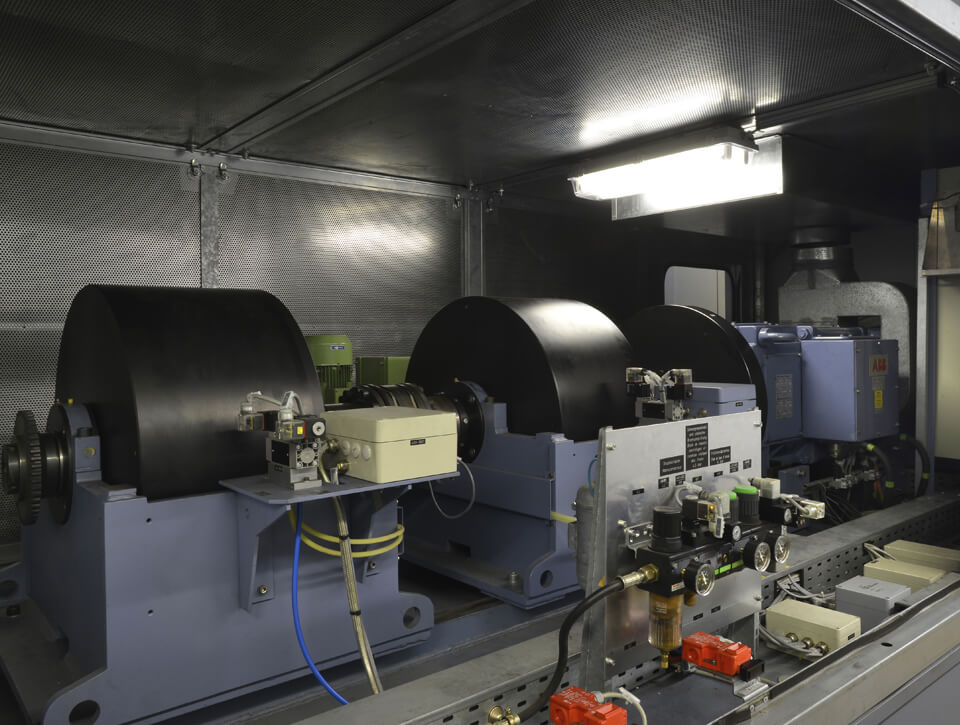

Dynamometric brake test bench

For carrying out characterization, performance, and pad wear tests, together with tests on characterizing the thermomechanical behavior of the disk/pad unit and characterizing noise vibration harshness , using standardized or internal methods

Brand SCHENCK

Power: 190 kW

Maximum speed: 3,500 rpm

Inertial range: from 10 to 220 kg.m²

Maximum continuous torque: 1400 Nm. from 0 to 1650 rpm

Hydraulic pressure: from 0 to 160 bar

Test enclosure temperature: from -20°C to +50°C

Humidity: from 15 % to 80% RH

Maximum wheel diameter allowed: 1m from 0 to 900 rpm

Hand-brake system, load: 5kN, course 100mm

Main torque measurement: +/- 300Nm and +/- 4000Nm

Residual torque measurement: +/- 200Nm

Regulation: Pressure, torque, deceleration

Master cylinder displacement: 0-50mm

Instrumentation: Type K thermocouples (1000°C) – 4 rotating channels by remote measurement and 4 fixed channels, 8 voltage channels, pulse per rotation, Brüel & Kjaer vibro-acoustic acquisition system, 5 rapid channels 25.6kHz and 16 slow channels 10Hz